|

MQ-1 Predator Drone of the kind used to wreak death, destruction and terror in Pakistan's Swat Valley September 2009. Two million refugees; Obama's Guernica.

On Making a Cardboard Drone

Introduction

During March 2010, US President Barack Obama was scheduled to visit Canberra and address the Australian Parliament. The announcement was sparse on detail. The first date proposed was 23 March and this was later changed to 26 March and then postponed till June.

On behalf of Stand Fast, veterans against the Iraq and Afghan wars, veteran peace activist, Graeme Dunstan, set out to organise a "drone attack welcome".

The idea was to create a small fleet of slogan-bearing drones to capture the attention of the national and international media reporting on the visit.

The philosophy was that when the peace movement is as weak as it is now and one cannot expect big crowds to mobilise in dissent, one must be artful.

Via Facebook and email networks of anti war groups, the drone making attracted a lot of interest at home and abroad, including organisers from CodePink, Women for Peace who had been thinking along the same lines. Below the drones they made and had on display at their protest march in Washington DC on the 7th anniversary of the Afghan War. See CodePink pix.

Maybe Obama will come to Canberra in June 2010 as promised. Maybe not. Whatever a drone fleet is in preparation.

What follows is making instructions for a cardboard drone of the MQ-1 variety. You will note this model is not the least bit aerodynamic. Rather they are 3D placards designed to carry slogans and catch the eye.

Materials and Tools

The body is made of 92 mm dia mailing tubes and the underwing rockets 62 mm dia.

I chose mailing tubes because they are cheap and readily available. But I discovered that they are made from poor quality cardboard which is structurally weak. It also absorbs moisture and gets soft in damp air and what's more it is coated with a paper which is poorly adhered and peels off under stress. Next time i make a drone i make them more enduring by using PVC drain pipes for the body and rockets.

The head was sculpted from corrugated cardboard salvaged from a white goods store. Corrugated cardboard is an excellent material for making stuff. It costs nothing, is easy to cut, easy to glue, ready to paint, lightweight and structurally strong.

The wings and fins are made from 6 mm three ply. Cardboard would have been too weak for the spans involved. I tried 3 mm MDF (medium density fibre board) which is very cheap but I found it likewise too weak.

For the blades of the propellor i used corflute, a corrugated polythene used for by real estate agents and politicians to make placards. It likewise is readily available to re-cycle, easy to cut, easy to glue and paint. What's more it is weather proof and bend resilient.

Tools included steel rulers and right angles, pencils, snap blade knives, hot melt glue gun and glue sticks, hand saw, jig saw, cordless drill and 16 and 20 mm spade bits.

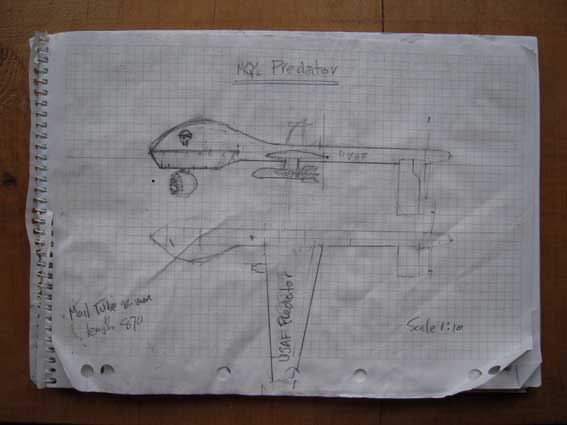

Step 1: Make a scale drawing

Using graph paper (5 mm squares) make a 1:10 scale sketch of the drone. This will serve as a guide to dimensions, shape and relative positions of the features. In drawing it, the diameter of the mailing tube was the critical dimension; all other bits were made in proportion to it.

Remember that the aim is NOT to reproduce a drone to exact dimensions. Rather the aim is to represent a drone, to make something that looks like a drone, and which emphasises its distinguishing features such as for example the sperm-like head, the distinctive splayed under fins and the propellor at the rear.

You can get 3D models of the MQ-1 Predator here.

Step 2: Sculpting the Drone head

As said earlier cardboard is good to work with, easy to cut and forgiving. If you make an error and cut too long, easy to trim. Too short, just glue on an extra bit.

The engineer in me likes to form the shape by marking and cutting out the plan and elevation of the features then slotting them together.

Hot melt glue gives a strong joint in just thirty seconds. If there is any stress in the joint, masking tape can be used to hold the cardboard in position while the glue sets.

Note that a 200 mm length of 16 mm dia dowel has been built-in to the head. This will eventually hold the spherical spy camera assembly (later to be represented a polystyrene ball) and also serve, along with the ends of the underfins at the rear, as a prop to support and protect the cardboard of the nose of drone when it is resting on horizontal surface.

Step 3: Cutting and assembling the wings and fins

As said earlier 6 mm three ply was used, cut with a hand saw, and the edges smoothed off.

To make the drone easier to transport say in a car, the model was made to be easily assembled and disassembled into bits.

Slots were cut in the body tube to receive the wings and the fins and these were designed to pass through the tube and overlap so that they could be fastened in place.

Step 4: Making and Assembling the Propellor

Moving parts attract the eye so i worked to make a propellor which would turn in the wind. To do this i used a piece of 16 mm dowel as an axle and a piece of 18 mm PVC drain pipe as an axle bearing.

In the first prototype i made the socket in the spindle too weak so I labored to ensure the second socket was stronger.

Assembled it looked like this.

Step 5: Making a socket to receive a holding pole

The drone will look much more impressive and threatening if it is held up and viewed from below. It will also be easier to carry if it is on a pole that can be propped on the ground. And having the pole removable makes the whole assembly easier to transport.

For a pole i used a piece of 30 mm by 18 mm pine timber 2 meters long.

I cut a rectangular hole in the cardboard tube and in the wing assembly too. I put a piece of 6 mm dowel through the pole so that the weight of the drone on the pole would be taken by the wings sitting on the lugs of this dowel.

In the photo above you can see that I reinforced the holes in the cardboard tube with three ply glued to the cardboard of the mailing tube with construction adhesive.

Step 6: Making and fitting the underwing rockets

To me, rockets with fins look more like rockets than the fold-away finned, slick tubes of death technology (two laser-guided AGM-114 Hellfire anti-tank missiles) with which the MQ-1 is armed.

I fashioned the rockets from 62 mm dia mailing tube and made them so that they could be slotted onto the wings and easily dissembled for transport.

I misjudged the length of the rockets and the first versions were too stumpy. I subsequently added an extra 10 mm of tube to make them longer.

Step 7: Painting

In the hope that an oil based primer would help seal the cardboard, I painted not only the plywood but also the cardboard with primer. Then painted it all with a white low-sheen acrylic.

There are a number of approaches to painting agitprop art. I come from the school that says black and white is best. Black and white emphasises the cartoon like caricature of the art. Black and white stands out by day and also by night. As you can see, I went for bold heavy lines.

That's the finished paint job sans the slogans which i later designed in a graphics program (Adobe Illustrator) on my laptop, printed off and glued on.

Here they are:

|